1. Introduction

AI in industrial automation is revolutionizing the way industries operate, bringing unprecedented levels of efficiency, precision, and innovation. By 2027, the global market for AI in manufacturing is projected to reach $16.7 billion, underscoring its transformative impact.

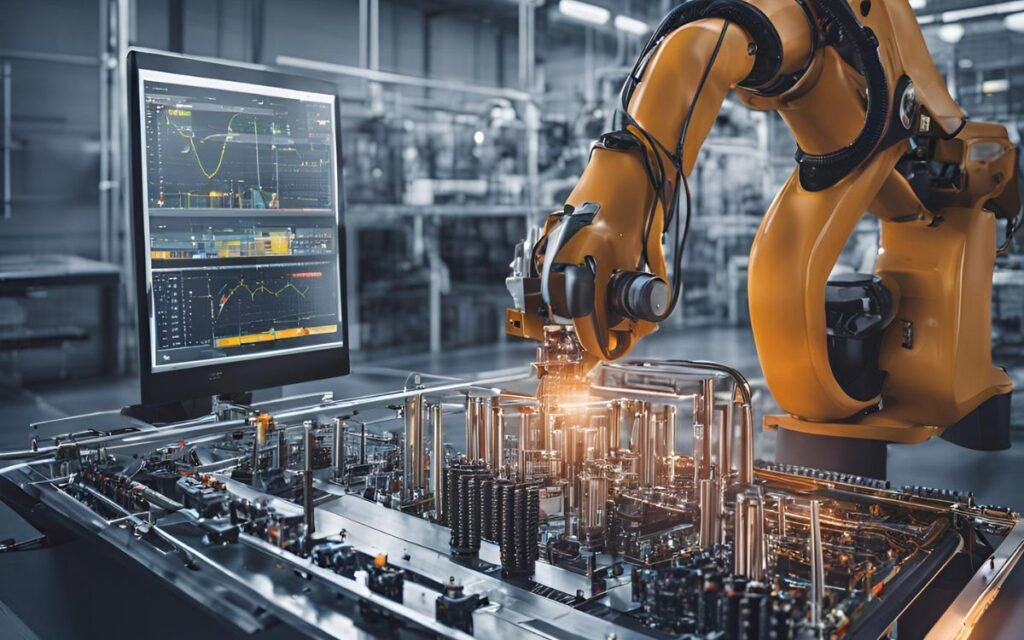

But what exactly is AI in industrial automation, and why is it such a game-changer? In simple terms, it’s the integration of artificial intelligence technologies—like machine learning, computer vision, and robotics—into industrial processes to automate and optimize operations.

In this blog post, we’ll dive into the key applications, benefits, challenges, and future trends of AI in industrial automation, and explore how it’s reshaping industries worldwide. Whether you’re a manufacturer, engineer, or business leader, understanding this technology is essential to staying competitive in today’s fast-evolving landscape.

2. What is AI in Industrial Automation?

AI in industrial automation refers to the integration of artificial intelligence technologies—such as machine learning, computer vision, and robotics—into industrial processes. Unlike traditional automation, which relies on pre-programmed rules, AI-powered systems can learn, adapt, and make decisions in real-time.

Here’s how it works:

- Machine Learning (ML): Algorithms analyze data to identify patterns and make predictions.

- Computer Vision: AI systems “see” and interpret visual data for tasks like quality inspection.

- Robotics: AI-driven robots perform complex tasks with precision and adaptability.

This combination of technologies enables smarter, more flexible, and efficient industrial operations.

3. Key Applications of AI in Industrial Automation

AI in industrial automation is being used across various industries to solve complex challenges. Here are some of the most impactful applications:

Predictive Maintenance

- AI analyzes sensor data to predict equipment failures before they happen.

- Reduces downtime and maintenance costs.

- Example: Siemens uses AI to monitor turbines and prevent unexpected breakdowns.

Quality Control

- AI-powered visual inspection systems detect defects with higher accuracy than human inspectors.

- Ensures consistent product quality.

- Example: BMW uses AI to inspect car parts for defects during production.

Process Optimization

- AI analyzes production data to identify inefficiencies and optimize workflows.

- Reduces waste and improves resource utilization.

- Example: General Electric uses AI to optimize energy consumption in factories.

Supply Chain Management

- AI predicts demand, optimizes inventory, and improves logistics.

- Reduces costs and improves delivery times.

- Example: Amazon uses AI to manage its vast supply chain network.

Robotics and Cobots

- AI-driven collaborative robots (cobots) work alongside humans to enhance productivity.

- Perform repetitive or dangerous tasks with precision.

- Example: ABB’s YuMi cobot assists in assembly lines.

4. Benefits of AI in Industrial Automation

The adoption of AI in industrial automation offers numerous benefits:

- Improved Efficiency: AI optimizes processes, reducing production time and costs.

- Cost Savings: Predictive maintenance and waste reduction lower operational expenses.

- Enhanced Quality: AI ensures consistent and high-quality output.

- Increased Safety: AI-powered robots handle hazardous tasks, reducing risks for workers.

- Scalability: AI systems adapt to changing production demands.

These advantages make AI a must-have for industries looking to stay competitive.

5. Challenges and Limitations

While AI in industrial automation offers immense potential, it’s not without challenges:

- High Initial Costs: Implementing AI systems requires significant investment.

- Data Privacy Concerns: Handling sensitive industrial data raises security issues.

- Skill Gap: A shortage of skilled workers to manage AI systems.

- Integration Challenges: Legacy systems may not be compatible with AI technologies.

- Ethical Concerns: AI decision-making must be transparent and fair.

Addressing these challenges is crucial for successful AI adoption.

6. Future Trends in AI and Industrial Automation

The future of AI in industrial automation is bright, with several exciting trends on the horizon:

- Edge AI: Real-time data processing at the source for faster decision-making.

- Digital Twins: Virtual replicas of physical systems for simulation and optimization.

- Autonomous Factories: Fully automated factories powered by AI.

- AIoT (AI + IoT): Integration of AI with the Internet of Things for smarter industrial ecosystems.

- Generative AI: AI-driven design and prototyping for faster innovation.

These trends will further revolutionize industrial automation in the coming years.

7. How to Get Started with AI in Industrial Automation

Ready to embrace AI in industrial automation? Here’s how to get started:

- Assess Your Needs: Identify areas where AI can add the most value.

- Invest in Data Infrastructure: Ensure you have the tools to collect and analyze data.

- Partner with Experts: Collaborate with AI solution providers for seamless integration.

- Train Your Workforce: Upskill employees to manage and operate AI systems.

- Start Small: Implement pilot projects to test and refine AI solutions.

Taking these steps will help you unlock the full potential of AI in your operations.

8. Conclusion

AI in industrial automation is no longer a futuristic concept—it’s here, and it’s transforming industries at an unprecedented pace. From predictive maintenance to autonomous factories, AI is driving efficiency, innovation, and growth.

The benefits of AI in industrial automation are clear: improved productivity, cost savings, enhanced product quality, and safer working environments. However, businesses must also address challenges like high initial costs, data security, and the need for skilled workers to fully harness its potential.

As we look to the future, trends like edge AI, digital twins, and AIoT promise to take industrial automation to new heights. Companies that embrace these advancements today will be better positioned to thrive in an increasingly competitive landscape.

The question is, are you ready to join the revolution? Start exploring how AI in industrial automation can transform your operations and unlock new opportunities for growth. The future of manufacturing is smart, efficient, and driven by AI—don’t get left behind.